The Ministry of Steel has prepared a draft steel scrap policy, envisaging a framework to facilitate and promote the establishment of ferrous scrap/steel scrapping centres in India. Availability of right quality of scrap, in adequate quantity, is one of the critical factors for future growth of both the EAF/IF sectors and keeping this objective in view and in order to develop a globally competitive steel industry by adopting a state-of-the-art environment-friendly technologies, the ministry has come up with the much-awaited draft policy. All stakeholders are requested to submit comments latest by 14th July, 2019.

While iron ore remains the primary source of steel making, used or re-used steel in the form of scrap is the secondary raw material for the steel industry. As on March 2019, 1128 EAFs & IFs are operating in the country and largely depend upon scrap as a raw material to produce steel. The use of every tonne of scrap shall save 1.1 tonnes of iron ore, 630 kg of coking coal and 55 kg of limestone, it added.

Why is there a need for the policy?

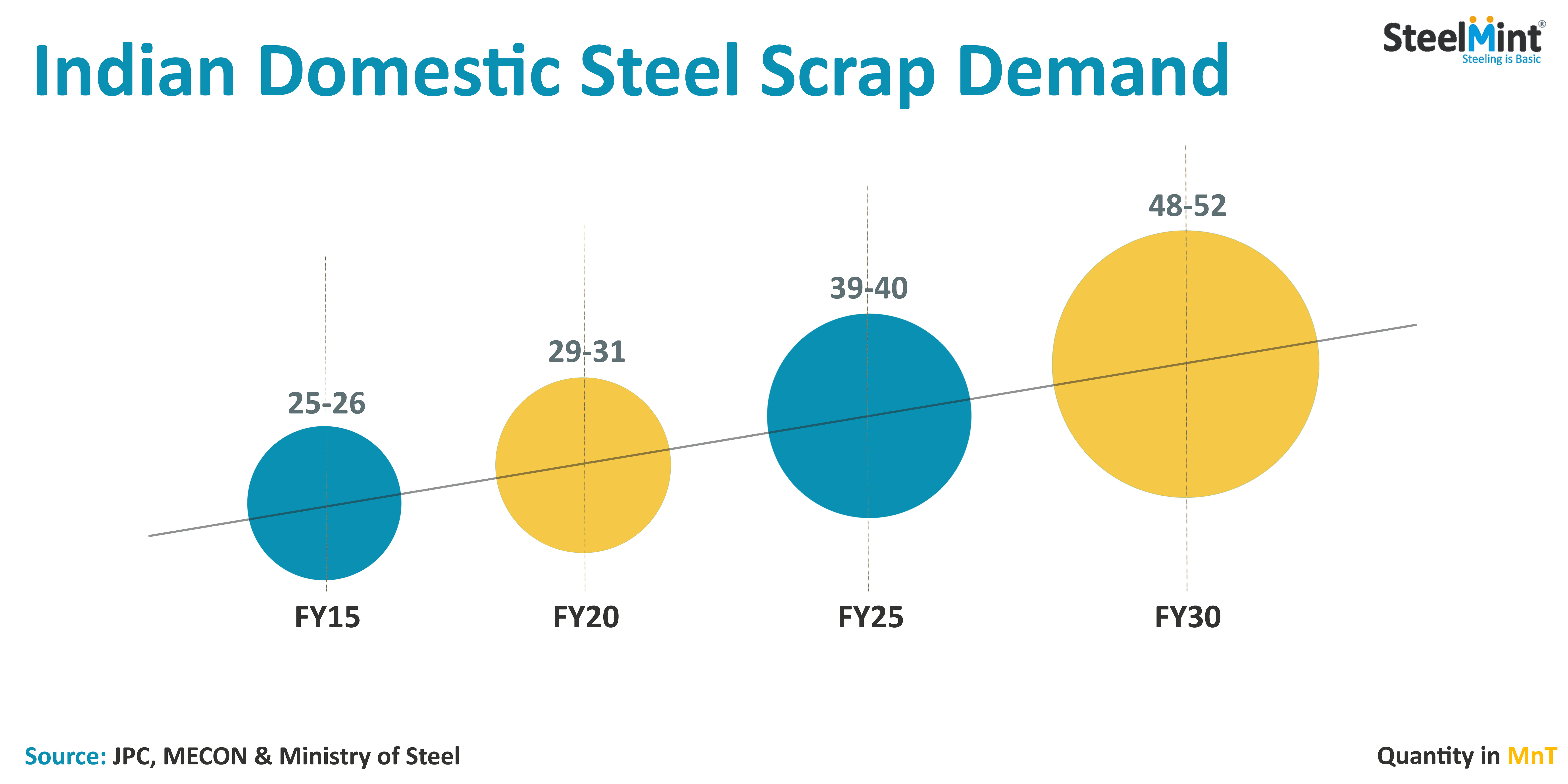

The availability of scrap is a major issue in India and in 2017 the deficit was to the tune of 7 million tons (MnT). The gap between demand and supply is likely to be reduced in the future and the country may be self-sufficient by 2030.

The efficient use of scrap for steel production becomes very crucial for India as 35-40% share has been envisaged from scrap-based steel production in the journey of 300 million TPA by 2030. This shall increase requirement of steel scrap from the present level of around 25 MnT to more than 50 MnT by 2030. This is mainly because with the increase in consumption of steel in the recent past and ELVs, the generation of scrap is likely to be increased considerably. This scrap has to be channelized so that the same can be utilized for steel production in an environmental-friendly manner.

What are the objectives of the Indian steel scrap policy?

· To promote circular economy in the steel sector

· Processing and recycling of products in an organized, safe and environment-friendly manner.

· To produce high quality ferrous scrap for quality steel production, thus minimizing the dependency on imports.

· To decongest the Indian cities from ELVs and reuse of ferrous scrap.

· To create a mechanism for treating waste streams and residues produced from dismantling and shredding facilities in compliance with the Hazardous & Other Wastes (Management &Transboundary Movement) Rules, 2016 issued by MoEF&CC.

· To promote 6Rs principles of Reduce, Reuse, Recycle, Recover, Redesign and Remanufacture through scientific handling, processing and disposal of all types of recyclable scraps, including non-ferrous scraps, through authorized centres /facilities.

How will the working model be?

The increased production of vehicles and increased use of consumer durable and white goods in the last two decades and their rapid obsolescence shall generate large quantities of end-of-life products. This shall result in the generation of a continuous flow of large ferrous scrap for recycling in steel production.

The collection and/or dismantling centre should either set up by or be associated with a scrap processing centre.

Logistics may be one of the main challenges for safe and cost-effective transport system for inbound unprocessed products/scrap and outbound processed scraps to the melting shops. Thus, scrapping centres (collection-cum-dismantling centre and recycling centre) need to be supported by an adequate logistic facility in consonance with the National Logistic Policy.

In order to know more on Indian steel scrap demand-supply scenario, domestic generation & imports, book your seat at SteelMint’s 4th Steel Scrap, Billet & DRI Trade Summit being organised during 27-29th August, 2019 in Bangkok, Thailand.